What Tesla’s Electric Semi Truck Means for Cars and Safety on the Roadway: A Truck Accident Lawyer’s Review

On December 1, 2022, the first Semi Tesla trucks were delivered to PepsiCo. At the delivery event, Tesla, along with Elon Musk, showcased to the world the truck’s economic advantages, design, and what they believe to be the future of the trucking industry.

Additional orders are being prepared for companies and independent owner-operators who have also bought into the electric semi-truck revolution. But as these trucks roll out of the production line, what impact will they have on passenger vehicle safety, and can they reduce the number of truck wrecks that have plagued the industry for decades?

To answer these questions, we first need to understand the types of crashes that 18-wheelers are typically involved in and what types of wrecks can be potentially prevented or reduced by the enhanced, standard, built-in safety features that the new Tesla semi boasts.

A truck accident lawyer will commonly deal with 18-wheeler wrecks that dramatically impact the lives of those involved. In this article, we’ll have a look at some of the most common causes of big truck accidents and the types of wrecks that can happen, which of these may be impacted by the new Tesla semi design and features, and which will likely continue to be major issues for fleets and passenger vehicles across the country.

Blind spot crashes and collisions

According to the National Highway Traffic Safety Administration (NHTSA), there are over 800,000 blind spot collisions each year, resulting in an average of 300 deaths. The “no-zone” of a commercial truck, or the areas surrounding the truck where the operator has no line of sight, can be extremely dangerous for a passenger vehicle; however, even with these risks known, blind spot detection systems are not required by the U.S. Department of Transportation.

Commercial trucks towing a trailer have four primary no-zone spots:

- Front No-Zone: Within 20 feet of the front of the truck

- Rear No-Zone: Within 30 feet of the rear of the truck

- Left No-Zone: One lane on the left side of the truck, near the cab

- Right No-Zone: Two lanes to the right of the truck, starting at the cab and slanting diagonally

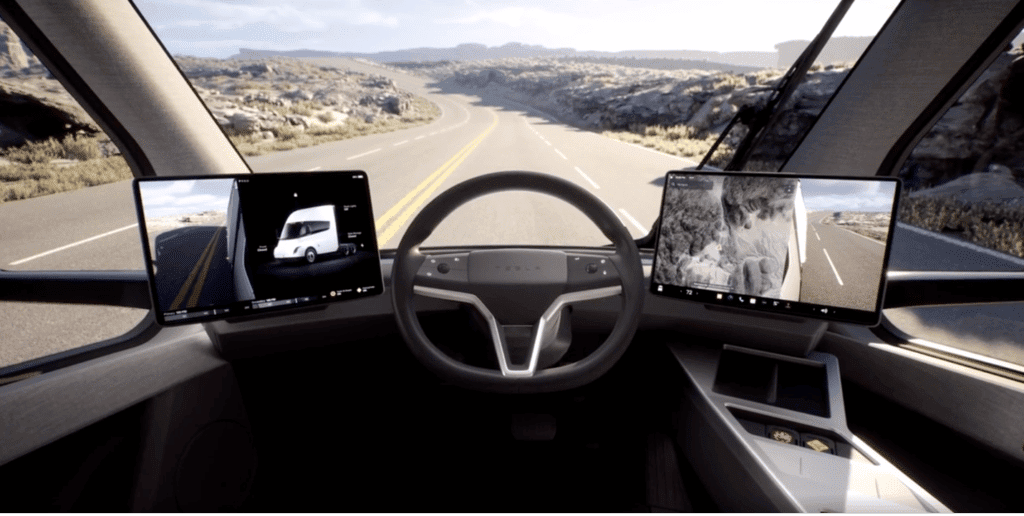

Now, let’s take a look at the interior of the Tesla semi

The first thing you’ll notice is the centered position of the steering wheel within the cab. The centering of the steering wheel gives the driver optimal visibility while addressing some of the issues with the right-side no-zone that extends a whole two lanes to the right of a typical diesel truck. There are also built-in cameras and widescreens, in addition to the mirrors, for maximum visibility on both sides of the tractor.

Clearly, this is a big win for blind spot safety; however, there are some things to keep in mind

The features shown here are exclusive to the tractor, but the tractor is only one part of the challenge when it comes to blind spot safety and reducing truck accident injuries. We also need to take the trailer into consideration and understand that drivers will haul many different brands of trailers with different load sizes and varying heights. What is not addressed by Tesla are the blind spots associated with the trailer or in the rear. Although full specs have yet to be released, it appears that rear cameras and sensor systems that would attach to the trailer will not be a part of the Tesla semi package.

So, for blind spots and no-zones, there is still a bit to go, it seems, but Tesla is certainly on the right track. Passenger vehicles should continue to be cautious and mindful of a tractor-trailer’s no-zones. Even the Tesla semi will have challenges in this area.

Electric semi-trucks are allowed to weigh 2,000 more than diesel trucks

Your typical tractor-trailer, under law, is allowed to weigh no more than 80,000 pounds at any given time, including when the trailer is loaded. Electric semis, however, are granted an extra 2,000 pounds, totaling 82,000 pounds, to accommodate for the weight of the battery required to fuel them. This gives fleets that are interested in electric trucks the incentive to know that they will not need to reduce their loads by 2,000 pounds.

In terms of safety, the force of 80,000 pounds versus 82,000 pounds striking a passenger vehicle may not seem like much of a difference, but it is a difference worth noting since the added weight does pose a larger risk for a car and potentially greater injuries in a truck accident collision.

Battery charge time and driver fatigue

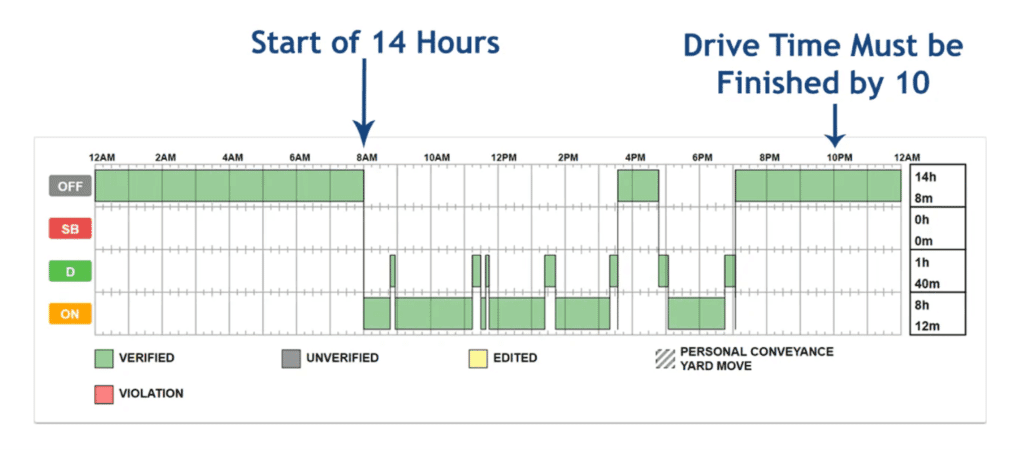

According to Tesla, it will take approximately 30 minutes to charge the battery back to 80%, which should get the driver roughly 400 miles, or about 7-8 hours. Commercial truck drivers are allowed a 14-hour workday, but they can only drive for 11 of those hours. The remaining 3 hours are for meals, breaks, etc. This is a strict start/stop schedule, meaning that if a driver begins driving at 8:00 a.m., they cannot drive past 10:00 p.m. Additionally, drivers are required to take a 30-minute off-duty break after no more than eight hours of driving.

So, the 14-hour window might look something like this:

Research conducted by the Insurance Institute for Highway Safety (IIHS) regarding driver fatigue shows that drivers who are behind the wheel for more than eight hours are twice as likely to crash, which is a big reason why a 30-minute break is required at that eight-hour period point. The Tesla semi can only drive for roughly 7-8 hours before it requires charging, which aligns well with the regulations. The challenge here may be the accessibility of Tesla’s “Megacharger” charging stations that will be available on the road.

What a lack of Megachargers means for the Tesla semi and driver fatigue-related truck crashes

Drivers of Tesla semis may be less likely to experience driver fatigue and related crashes simply due to the deficiency of Megachargers available to allow for long hauls. In the short-term, Tesla semis will, for the most part, likely be restricted to trips that do not extend beyond the 400-500 range of the battery. There will be few places for the trucks to stop and recharge, so longer trips may be problematic until the charging infrastructure is in place.

As truck accident attorneys, we see a number of victims who have suffered as a result of negligent truckers and fatigue. Although electronic logbooks are required, this system is often abused, and the results can be devastating. In the short term, while the Megacharger infrastructure is being built, shorter trips should mean less fatigue and, as a result, fewer truck accidents caused by fatigue. However, we need to remember that because Tesla semis are still a very small portion of all big rig trucks on the road (less than 1%), collisions involving big trucks due to fatigue are not likely to decrease anytime soon.

“Jackknifing is impossible in this truck,” says Elon Musk

As a commercial truck accident law firm, we see several catastrophic injuries due to different types of tractor-trailer instability. In many cases, we investigate causes and present these to the court or in settlement negotiations with trucking companies. One type of truck wreck we commonly deal with is collisions and injuries due to jackknifing.

Jackknifing has long been a danger for both truck drivers and passenger vehicles. Jackknifes are typically caused by instability due to braking or turning too quickly, empty trailers, or inclement weather. Tesla’s design helps reduce jackknifing two-fold.

On the one hand, the truck comes equipped with sensors to detect instability. This is a standard safety feature that will indicate to the driver if there is an issue. But Tesla did not make a passive truck, so in addition to alerting the driver, the truck reacts to the instability by applying positive or negative torque to each wheel while distributing brake functions independently as needed. This reduces the chances of jackknifing dramatically.

If what Musk says is true, and jackknifing is a thing of the past, then passenger vehicles and truck drivers will be a lot safer on the roadways in the future.

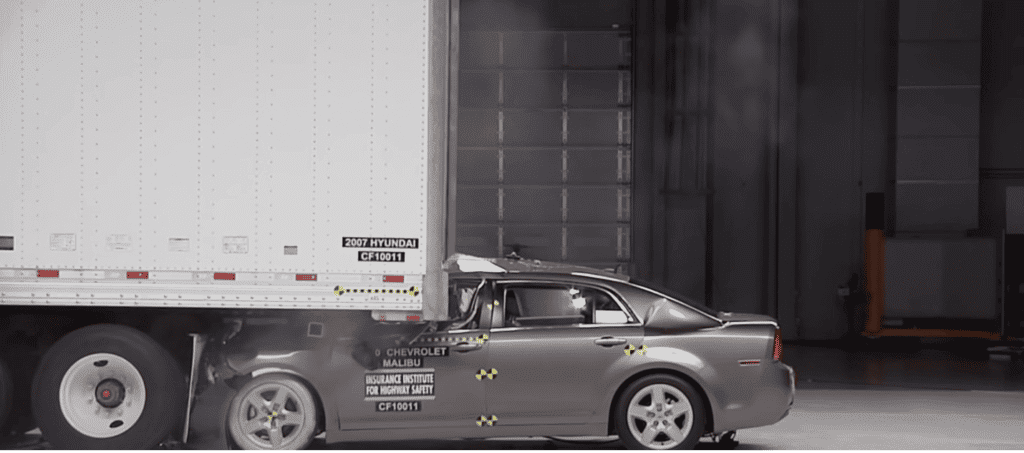

Underride crashes are still a dangerous risk

Although Tesla has made serious strides in the tractor’s safety, one element that they do not have control over are the risks associated with the trailer. Underride crashes are some of the deadliest collisions that can happen between a car and a tractor-trailer, and there is still a long way to go for the trucking industry and governing bodies to ensure proper engineering of underride guards, which can help prevent death and other catastrophic injuries.

What does an underride crash look like?

To put it lightly, underride crashes are absolutely devastating. They can literally peel the top half of a passenger vehicle right off its body. The impact shreds the front the car, and most people who are caught in an underride accident do not simply walk away without injuries.

The Federal Motor Carrier Safety Association (FMCSA) has required trailers to have underride guards in place since 1999; however, as truck accident lawyers, we continue to see fleets either not installing these guards or installing old, outdated guards that do not protect passenger vehicles from the wrath of an underride. Unfortunately, commercial trucking companies often look to their profit margins before the safety of cars and other drivers on the road. This will be a risk that the Tesla semi will have to tow for some time.

The end of runaway trucks? Probably not, but a good start.

There are multiple causes for a runaway truck. When coming down a steep incline, a truck’s brakes can often overheat, causing the truck to “run away” or become unable to stop. The brakes simply can’t hold up to the sheer weight of the truck, and they give out. Our truck wreck attorneys have also seen cases where trucking companies are negligent and do not ensure the mechanics are maintained or that worn-out brakes are replaced when needed.

Another cause of a runaway is if a truck picks up too much speed, it becomes impossible to downshift without destroying the transmission. In this case, the driver of the 18-wheeler will opt for a runaway ramp to avoid damaging the engine. Unfortunately, one in four trucks that attempt this are not successful. Runaway truck wrecks happen approximately 4,000 times a year and often end in injury or death to drivers of passenger vehicles.

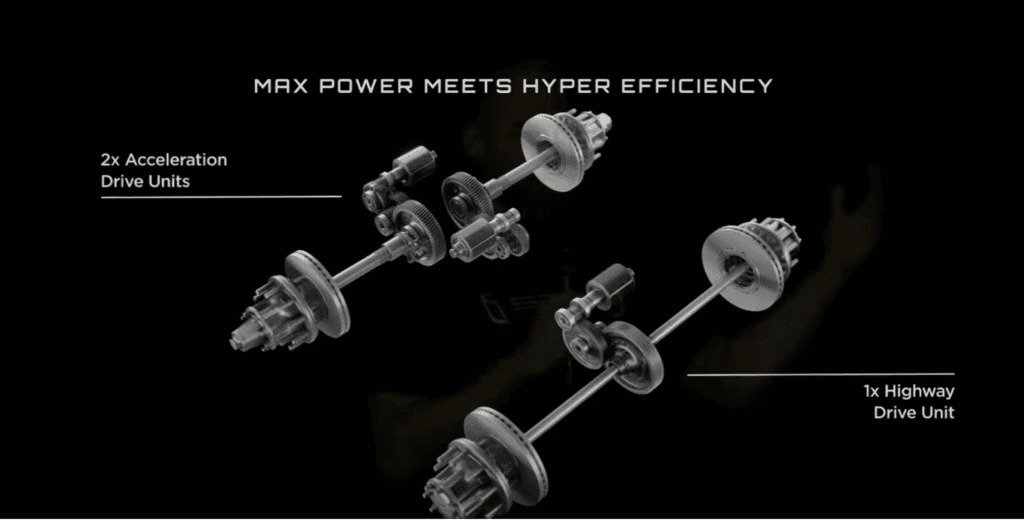

Tesla offers a solution to runaway trucks by means of regenerative braking. Like all electric vehicles, when the brake is applied, the engine essentially begins to run in reverse to recharge the battery. The Tesla semi uses a tri-drivetrain motor system. One highway unit is always engaged and does the bulk of the work, while the other two units are for torque and acceleration. What makes these units unique is how they work together. They are clutched automatically, so there is no driver input needed. The torque and acceleration units start and stop before the primary unit reaches its capacity, so there is a smooth transition when speeding up or when slowing down. This essentially solves the downshifting issues that diesel trucks will continue to have and should also put less strain on the brakes as an operational rule. It’s also worth noting that the primary motor (the one doing most of the work, most of the time) is about the size of a football.

As truck accident lawyers, we’re happy to hear that the Tesla semi-truck engineers have taken upshifting and downshifting into consideration because the difference between a safe truck and a dangerous one is often in details like this. If this system results in one less runaway truck accident injury, we are all for it.

Tesla semis are the minority (for now), but the future is hopeful

There are several unique and positive attributes that the Tesla semi offers, and we look forward to seeing more on the road, but we need to remember that they are still a very small minority and that classic semis are likely to be on the road for quite some time. Commercial trucks will continue to be very dangerous, especially when maintained by a negligent company or driven by a tired or otherwise negligent driver. Our team is hopeful that the Tesla semi will lead other fleets to innovate and make the roads a little safer for everyone.

Why Choose Ron Bell Injury Lawyers?

We Get Results!